rockwell hardness test hrb vs hrc|rockwell hardness test explained : exporter exporters exporting HRB: It is the hardness obtained by using a 100kg load and a hardened steel ball with a diameter of 1.58mm, which is used for materials with lower hardness (such as annealed . 26 de ago. de 2023 · Fãs catarina paolino ️. Aves; 26/08/2023; 545 views; Informar erro; Bem vindo grupo adulto de vídeos fotos 🔥 ️🔥🔥 catarina paolino ️🔥 . Seja ativo! Veja regras do grupo Proibido qualquer ato ilegal! Regras: Proibido invadir pv; Proibido conteúdo agressivo; Proibido uso de palavrões; Proibido travas;

{plog:ftitle_list}

webNew customer only • 19+ • Valid only for players in Ontario • $10 min deposit • The Bonus will be applied once the full deposit amount has been wagered at least once with cumulative .

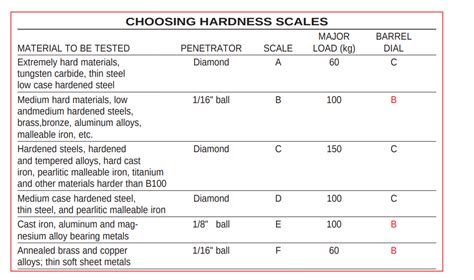

While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). This article compares two types of Rockwell hardness to help you find the . This table shows approximate hardness of steel using Brinell, Rockwell B and C and . HRB: It is the hardness obtained by using a 100kg load and a hardened steel ball with a diameter of 1.58mm, which is used for materials with lower hardness (such as annealed . A, B and C in HRA, HRB and HRC in Rockwell hardness are three different standards, called scale A, scale B and scale C. Rockwell hardness test is one of several .

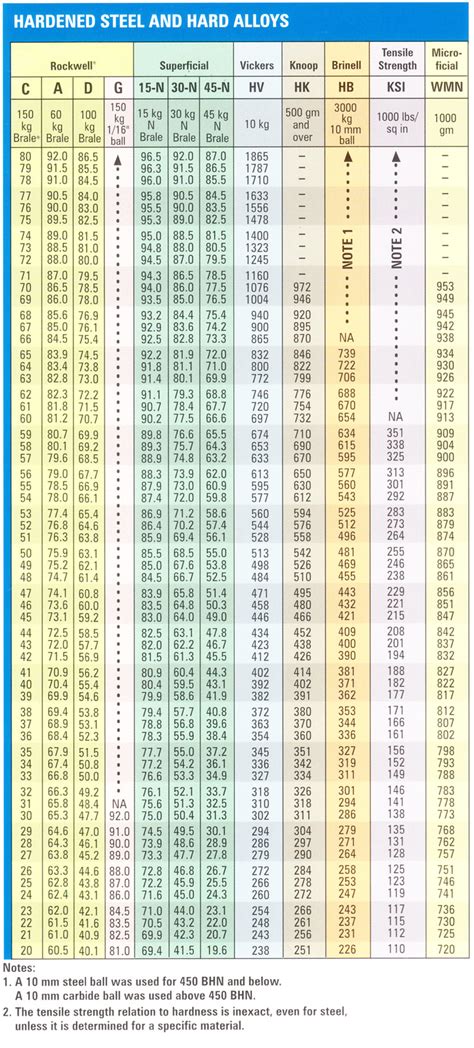

Converting Rockwell hardness involves using specific formulas or tables designed for the particular Rockwell scale (A, B, C, etc.) and the target hardness scale. The process typically . The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale. Larger numbers correspond to harder materials. When testing metals, indentation hardness correlates . Hardness comparison. A variety of hardness -testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases .These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship among Brinell hardness, Vickers hardness, Rockwell superficial, hardness, .

Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from . When the Brinell hardness test cannot be used, such as when the material’s HB value is greater than 450 or the sample size is too small, the Rockwell hardness test is used instead. This test involves pressing either a .Hardness Conversion Formula. Y = aX^2 + bX + c. Where: Y is the hardness value in the target scale; X is the hardness value in the original scale; a, b, and c are constants determined through empirical testing; Example: Converting Brinell (HB) to Rockwell C (HRC) for steels:. HRC = -0.000000567 HB^2 + 0.0624 HB – 13.7. Using this formula, we can convert a Brinell hardness .Hardness scales Hardness according to Rockwell (HRc - cone and HRb - ball) The depth of penetration of an indenter is measured by loading a certain force. Either a ball (HRb) or cone (HRc) can be used. It is a quick and simple measurement, especially suitable for cutlery steels. Vickers hardness test (HV) A pyramidal diamond indenter with a 136 .

Rockwell C HRC (120 degree cone 150 kg) Rockwell B HRB (1/16" ball 100 kg) Leeb HLD [1] 800-72-856 780: 1220: 71-850 760: 1210: 70-843 745: 1114: 68-837 725: 1060: 67-829 . -12B(2019)e1: "Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

Different scales, such as Rockwell C (HRC), Brinell (HB), Vickers (HV), and Rockwell B (HRB), are employed to quantify the hardness of steel and other metals. Each scale offers unique insights into a material's mechanical properties, making it crucial to be able to translate hardness values from one scale to another accurately. The hardness of steel depends on several factors, such as its composition, manufacturing, and heat-treating processes.The different hardness scales use different loads, different indentor shapes, and different measurements to obtain the hardness number. There are no straightforward formulae to establish relationships between the different scales, making .Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship among .For instance, converting from a Rockwell hardness test on the C scale (HRC) to a Brinell hardness test value requires using the formula: BHN = 5.970 x (HRC + 104.7). This formula gives an approximate value for the Brinell hardness value, and quality assessment professionals use it to create the conversion tables and charts for instant conversion.

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine .Rockwell Hardness (HRC and HRB) and Brinell Hardness (HB or BHN) are most commonly used for steel and iron castings. Although there is no accurate conversion tables and equations, but dandong foundry recommend the following formulas and comparison tables according to the experience and standards. Formula A - Convert HRC into HB .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

The Rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the Rockwell formula. The resulting value is then translated to the Rockwell C scale of hardness to determine the hardness of the material. . Example 1: A regular Rockwell hardness method (HRC) 45 HRC. The number 45 represents the . HRC (Rockwell C Hardness) and HRB (Rockwell B Hardness) are scales measuring material hardness; HRC is used for harder materials, HRB for softer materials. Key Differences. HRC, or Rockwell C Hardness, . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: . HRC – Known as “Rockwell C,” a 150 kgf load is applied .

The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate. Brinell Hardness: . FREE Mill Test Reports Save on your Mill Test Reports and Certs of Conformance. They're always FREE at OnlineMetals.com. Learn More. Knowledge Hub . In the Rockwell test, an indenter is pushed into a metallic surface with a given force. . The Rockwell C scale is usually abbreviated HRC (Hardness Rockwell C), while the Rockwell B scale is abbreviated HRB (Hardness Rockwell B). The higher the number, the harder the material, but only relative to other numbers within a given scale. For . The NIST HRC levels establish the hardness of materials slightly harder than the historical standards used in the United States for the past 75 years. . The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously . Perbedaan dalam Mengukur HRC dan HRB dengan Digital Rockwell Hardness Tester – . Perbedaan antara skala kekerasan Rockwell C (HRC) dan Rockwell B (HRB) merupakan faktor krusial dalam pengukuran kekerasan material menggunakan Digital Rockwell Hardness Tester. . [email protected]; 0857-1711-2222; Layanan Pelanggan. e-Katalog; .

custom general mm7 moisture meter calibration

The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . HRC 45 to HRC 55: Brass: HRB 55 to HRB 93: Hard Impact Steel Blades: HRC 52 to HRC .High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the

Where: HRC: Represents Rockwell Hardness on the C scale, a common hardness measure for harder materials.; HB: Represents Brinell Hardness, a measure of hardness obtained by pressing a hard spherical indenter into the material under a specific load.; Please note, the accuracy of these formulas can vary, and they are often used for approximate conversions .1/16" Carbide Ball Indenter Hardness test Block 60 HRC Hardness test Block 60 HRC . B HRB 980.7N (100kgf) 20-100HRB G HRG 1471N (150kgf) 30-94HRG H HRH Sphere ø3.175mm . *Dedicated to the Rockwell Superficial hardness test V-anvil (small) 810-041 (Outside ø40 mm, Groove width 6 mm)

The Rockwell Hardness test was invented by Stanley P. Rockwell. The Rockwell Hardness test also uses a machine to apply a specific load and then measure the depth of the resulting impression. Rockwell hardness number can be represented by HRB. When the material is very thin, lighter loads must be used, resulting in Rockwell 30T. . The Brinell hardness, Vickers hardness, Rockwell hardness, and Barcol hardness are for reference only and cannot be used for conversion. If conversion is required, it is recommended to use the hardness conversion table of the American standard ASTM E140. . Hardness Conversion Chart: HLD, HRC, HRB, HV, HB, HSD; Special Smelting: Everything .

typical rockwell hardness of materials

rockwell hrc scale chart

rockwell hardness test explained

A Revisão Oficial Automóvel realiza-se de acordo com as especificações do livro de manutenção do seu veículo.A MForce trabalha com uma base de dados técnica que contém mais de 28 marcas, 4.800 modelos e 100.000 planos de manutenção auto.. Assim, o sistema informático da MForce indica as intervenções a realizar em cada viatura em .

rockwell hardness test hrb vs hrc|rockwell hardness test explained